Meets Modern Technology

An Ancient Art

Welcome! I am an engraver and graphic designer from Katy, Texas. Most of my engraving work has been on knives, the majority of them for custom knifemakers here in Texas. My style of engraving evolved in an uncommon way, having started with laser engraving and later on learning traditional hand engraving techniques. Over time I have developed a way to blend these various methods in a way that uses the strength of each - thus the name “Hybrid Engraver”. My time is now split between engraving for clients and teaching others.

-Tyler Poor-

ENGRAVING METHODS

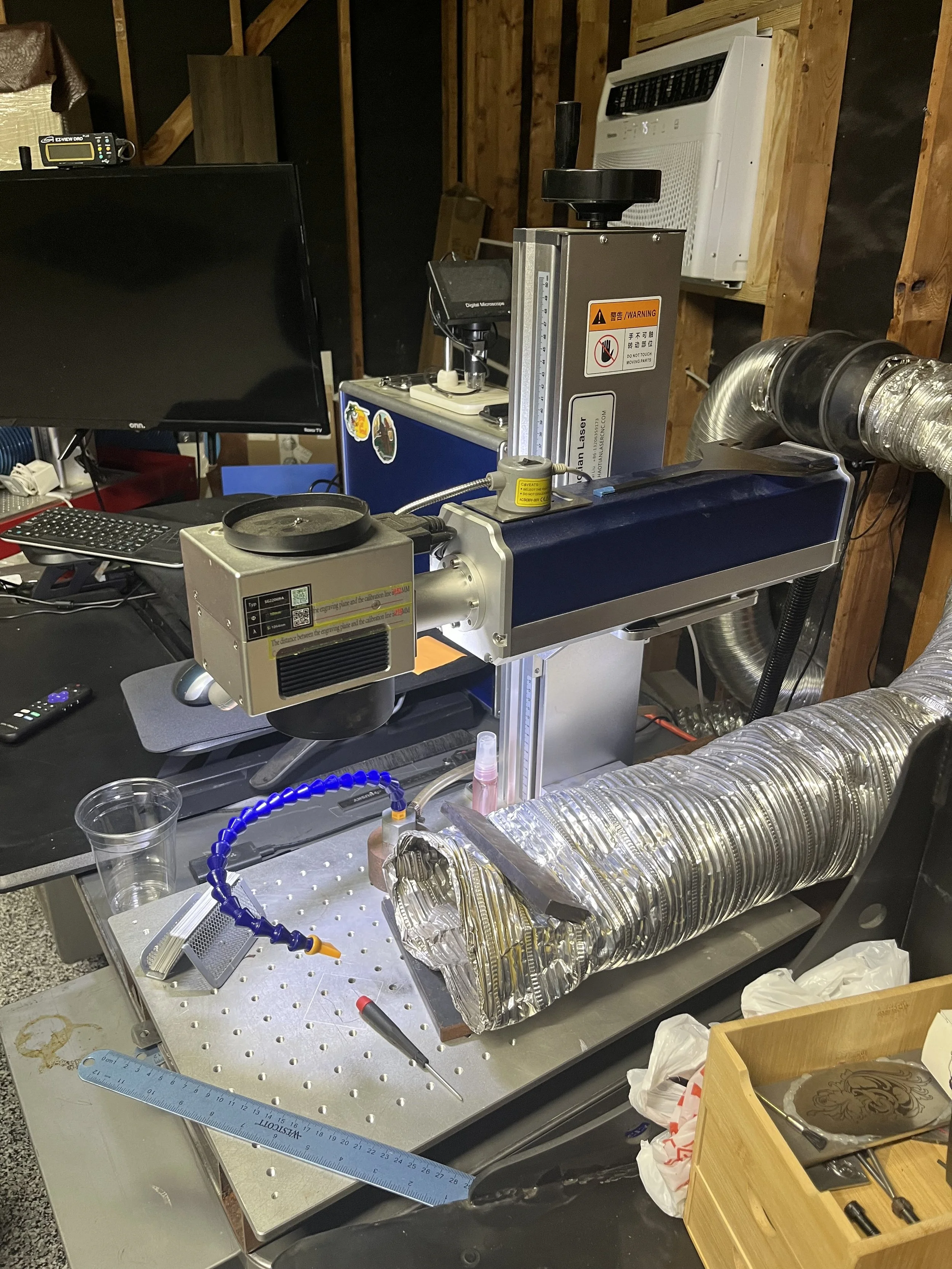

fiber Laser Engraving

-

-Engraves Stainless Steel, Brass, Copper, Titanium, as well as other metals and some plastic materials.

-

Can cut sheet metal up 14 gauge. Useful for cutting out silver overlays for spur bands/buckles.

-

The fiber laser can apply precise levels of heat to a metal like titanium or stainless and produce various colors through heat annealing.

-

Precisely removes coatings such as cerakote or powder coating and can even remove built up rust or rough finishes.

Hand Engraving

-

-My favorite style of engraving (pictured above), whereby a flat or square graver is used to make a beveled, flaring primary cut which is next back cut with an opposing bevel that creates a sculpted look to the design.

-

-Engraving executed by a hand engraver using a graver mounted in a power tool where the background is removed, and scrolls are finely shaded. I typically use the laser to mimic this style but if the project is important enough I will do by hand for extra detail.

-

-The process of inlaying gold or silver into a harder metal (either wire or sheet). Gives great contrast and value to an engraving piece.

CO2 Laser Engraving

-

-Engraves wood, leather, fabric, plastic and many other materials that the fiber laser cannot.

-

-Can cut up to 3/8" plywood, fiberboard, leather and other materials.

Hybrid Engraving

-

-The reason for my business name. Over time I have developed a method of using the strengths of both laser and hand engraving for efficiency and to save the customer money. This could be using the laser for doing the time-consuming task of background removal and then doing the shading by hand for fine detail the laser cannot achieve. Another example would be using the laser to cut a pocket for abalone (as pictured above) and then inlayed by hand. I believe using the right tool for the job is great for me and the customer, depending on the job.

Turning Dreams Into Reality!

From getting a laser to learning Procreate, Affinity Designer, or Lightburn I’m here to help you on your engraving journey!

Zoom or In-Person, schedule today to bring your designs to life